vacuum-forming

Our Vacuum-Forming Capabilities Are Endless

We specialise in vacuum-forming technologies and provide custom made components to meet your brand requirements. We manufacture to your specification and combining in-house extrusion facilities with our vacuum-forming capability, allows us to maintain our strong market position.

We also specialise in medium batch runs which further enables us to maintain customer satisfaction. With state-of-the-art thermoforming machines on site, we have the ability to tailor make trays, pallets, bases and lids to your individual requirements.

With nine vacuum-forming machines of different sizes, we can cost-effectively mould everything from small parts, to large components. Measuring in excess of 2400mm long by 1150mm wide and up to 650mm deep. All machines are equipt with dual-heating platens, enabling quicker cycle times and greater output.

our materials

Eco-Friendly Options Available

We can form a wide variety of extruded plastics, up to 10mm thickness in any colours and finishes, also wih pre-printed effects.

We regularly process materials such as ABS (in fire-retardant, recycled and other grades), polypropylene, HDPE, HIPS, Polycarbonate, PETG, and acrylic-capped ABS.

We are also highly proficient in forming parts in the exotic and high-strength materials Boltaron and Kydex.

We can work with 100% recycled materials to produce eco-friendly plastic products, we have a strong focus on sustainability.

Materials

ABS, HDPE, PP, HIPS, PC, PETG.

Grades

Fire retardant, recycled content, eco-friendly.

Delivering your specifications

Vacuum-forming Tailored To You

Our vacuum-formed products start with design. We have many years’ experience of tool design and with our CAD capabilities, this enables us to effectively and efficiently work with the customer to come up with the best design possible. We are very experienced in selecting the right material to use and quickly establish the optimal gauge to give the lowest cost product that works.

material thickness

1.5mm or greater

Operations

50,000 sq. ft.

Tooling technologies

Eco-Friendly Options Available

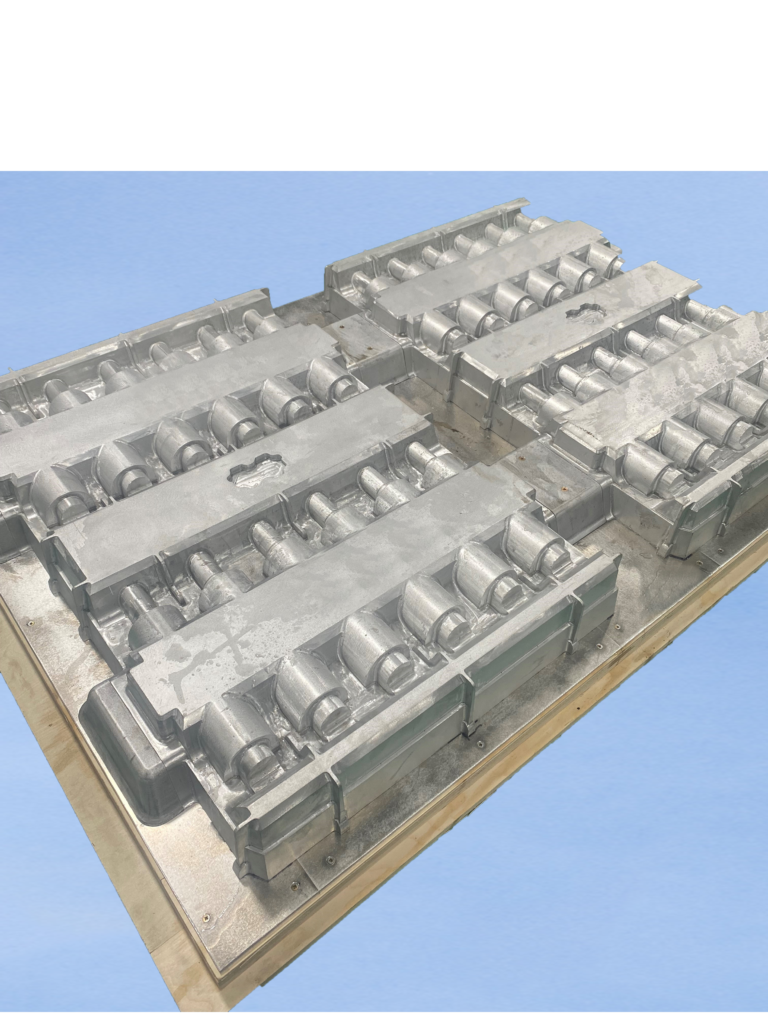

Toolmaking is normally carried out by our approved toolmakers under our control. Prototype tools are made to produce a small number of trial products to confirm the functionality. Once confirmed, aluminium tools are made. The aluminium tools can produce many thousands of products.

Some machines have sheet loaders and some with automatically variable plate apertures. Tooling is secured with quick release tooling clamps. These features significantly reduce the tool change over time and setting costs, this is very important and beneficial when running medium size batch production.

An additional benefit of having our own extrusion lines is that the skeletal trimmings around a vacuum formed product can be chipped and fed back into extrusion, at an appropriate percentage. This helps in our aim of reducing any waste going to land fill.

To ensure the security and safe condition of your goods and components, our moulded trays, racks and dividers provide innovative solutions to keep your items from damage during transit and storage. The different plate sizes we can offer are; 330mm x 330mm and 12350mm x 1350mm.

UK Tooling

Local toolmaking service.

Tool Prototyping

Prototype tools are available.