Sheet Extrusion

Sheet Extrusion Capabilities

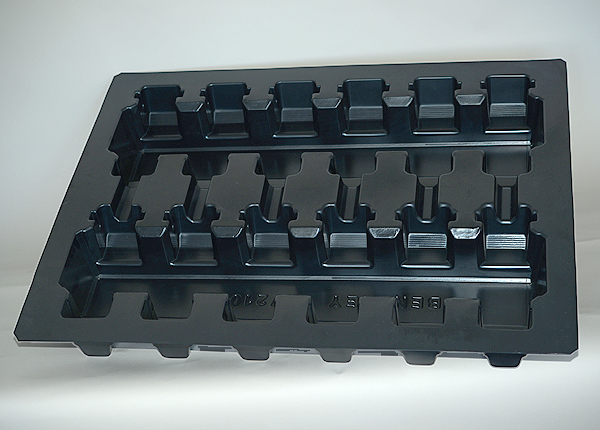

At Manplas Limited we are in a unique position, in that we manufacture our own high quality polyolefin sheet and rolls.

By using our multiple on-site extrusion lines, which operate 24 hours a day, we can extrude raw plastic pellet to customise any size, colour, finish, and prime/reprocessed polymer content you require. As well as any additional additives bespoke to your consumer requirements.

All our materials are thermoformable, machinable and can be fabricated into any bespoke customised project.

Get in touch if you’re looking for Plastic Extrusion Manufacturers in the UK.

Specification

Sheet Extrusion Specification:

- Thickness ~ Gauge can vary from as thin as 1mm up to 8mm (material dependant).

- Finishes ~ Smooth, pinseal, leathergrain and other bespoke material finishes can be acquired upon request.

- Size ~ Sheet capacity up to 1560mm wide and custom length, and roll capacity up to 1400mm wide and custom length.

- Colour ~ We can colour match to any requirement.

our materials

With a comprehensive range of polymers, we are confident to fulfil your customised demands. We can also custom blend polymers to your customised requirements and can colour match to your requirements.

- HDPE High-Density Polyethylene

- MDPE Medium-Density Polyethylene

- LDPE Low-Density Polyethelyne

- PP Polypropylene

- HIPS High Impact Styrene

- ABS Acrylonitrile-Butadiene-Styrene

- EO/POE - Ethylene Octane Polyolefin Elastomer

Additional Additives:

- Anti Static Properties

- Flame Retardant Properties

- Talc Fill

- Corona Treatment

- UV Protection

anti-static, talc fill & corona treatment

Our Anti-Static materials prevent charge generation on the extruded sheet surfaces and prevents electrostatic discharge.

We have a Static Eliminator, a bar-type static eliminator ionizes the air around it. Positively charged material, passing through ionized air, attracts free negative ions and becomes neutralized. Negatively charged material attracts positive ions and becomes neutralized. The result is a static-free sheet.

Our talc filled materials make the extruded sheet more rigid, adding strength and also holds the shape after moulding.

Our extruders have Corona Treatment capabilities.

A Corona Treatment system is designed to increase the surface energy of a plastic sheet to improve wettability and adhesion of ink. The treated sheet has improved printing properties and better strength.

Eco-Friendly Materials

We are future thinking, which is why all products can be made with 100% recycled materials. We can also add 70%, 50% or 30% recycled content into your material to create your product.

We also offer ‘End of Life’ recycling, in which we will take your used/unused plastic and skeletal waste. These are then granulated here on site and then re-extruded into further sheet and rolls. This enables a sustainable product (by closing the loop), we can create the exact size, finish, plastic content and colour you require.

All of our products here at Manplas Ltd are included in our End-Of-Life Recycling scheme. Customers simply return unwanted products/waste to us here at Manplas Ltd and we regrind and reuse for a new plastic project. This is supporting our circular economic focus.

Plastic Extrusion Manufacturers

At Manplas, our specialists use advanced technology to produce large volumes of plastic sheets to make signage, displays, piping, packaging for food, and much more. We use strong, durable, and flexible materials such as acrylic, polycarbonates, and PVC before cutting them to size as instructed by our customers.

We also offer a variety of colour and finishing solutions to choose from, including smooth, patterned, leather, or made-to-order designs that are available on request.

Serving industries such as aerospace, automotive, catering, construction, and rail, we’re known for our excellent customer care. From our initial conversation with clients as we gauge their expectations to manufacturing their products, we guarantee a hassle-free experience and offer attentive aftercare to ensure that they are happy with the results.

Plastic Sheets for Construction, Packaging, Signage, and More

Getting plastic sheets that do exactly what you need might sound simple, but anyone who’s faced it knows how simple missteps can cause real problems. Sheets can come out uneven, too weak, or with finishes that don’t look right.

As experienced plastic extrusion manufacturers, we make sure your sheets are consistent, strong, and ready to be used.

We know the challenges businesses face when sourcing plastic sheets, and we’re all too familiar with the ripple effects when things don’t go as planned. Warping, inconsistent thickness, or materials that don’t hold up under pressure can cause costly headaches further down the line. Our team works closely with you to get the extrusion process just right. Whether you need sheets for construction, signage, packaging, or industrial use, we focus on delivering materials that are easy to work with and fit for purpose every time.

A: You’re not locked into huge orders. Whether you need a handful of sheets for a small project or a full production run, we’ll make it work.

A: That’s our favourite kind of challenge. We can make your sheets to suit your needs exactly.

A: We’ve got your back. We are approachable, responsive, and ready to help troubleshoot or adjust if anything isn’t quite right. Problems happen and it’s how we handle them that counts.

A: Absolutely! We don’t just hand over sheets and walk away. We’ll talk through your project, look at what you’re trying to achieve, and help you pick the right material. It’s about giving you something that actually works for your needs, not just what we’ve got in stock.